Barry's Coilguns

Mark 4

- Introduction

- Objectives

- Schematic

- Projectiles

- Capacitor

- Kinetic Energy

- Timing

- Coil Design

- SCR

- Diode

- Damping Resis

- Bleeder Resis

- Iron Type

- Iron Shape

- Iron Size

- Low Voltage

- High Voltage

- Isolation

- Low Voltage Power

- Charging Resis

- Construction

- Firing Tube

- Retention Bolt

- SCR Wiring

- Transformer

- External Iron

- Purchases

- Speed Measurement

- Results

- Coil of 97 Turns

- Coil of 84 Turns

- Damping Resistor

- Burned Coil #1

- Coil of 56 Turns

- Eddy Currents

- Starting Position

- Conclusions

Coil #2 of 56 Turns

This was the fourth and final coil tested. The coilgun is in its finished form, with a fixed-voltage power source.

Coil #2 of 56 Turns

Because the power supply is now fixed at 160v, the testing consists of measuring speeds of all projectiles. See the Projectiles page for details of these projectiles. The projectiles are listed in order of mass.

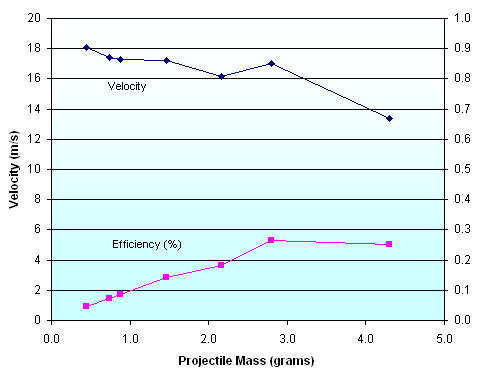

| Projectile | Description | Mass | Velocity | Velocity | Efficiency |

|---|---|---|---|---|---|

| (grams) | (m/s) | (feet/sec) | (%) | ||

| A | 3.5" finishing nail |

4.301 | 13.36 | 43.8 | 0.25% |

| B | 1.25" galv casing nail | 2.800 | 17.03 | 55.9 | 0.26% |

| C | 2.5" finishing nail | 2.163 | 16.15 | 53.0 | 0.18% |

| D | 2" finishing nail | 1.464 | 17.23 | 56.5 | 0.14% |

| E | 1.75" T-head nail | 0.872 | 17.26 | 56.6 | 0.08% |

| F | 1.5" finishing nail | 0.735 | 17.41 | 57.1 | 0.07% |

| G | 1.25" T-head nail | 0.442 | 18.06 | 59.3 | 0.05% |

Graphical Results

This graph compares the velocity and energy efficiency as a function of mass.

Efficiency

Although most projectiles fly at about the same speed, the heavier ones have better energy conversion efficiency.

The best efficiency of 0.26% is disappointing. We hoped for 1 – 2% efficiency with the use of external iron.

Additional testing using the same coil without the external iron, found much lower efficiencies in the range of 0.1% or less. Although it’s nice to know the iron makes four-times improvement in energy conversion, this is still very low.

We hope to find better coil geometries in the future that will improve energy conversion efficiencies.

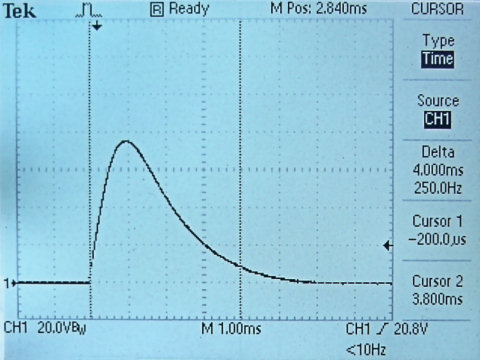

Coil Timing

The 56-turn coil measured a 4.0 ms half-cycle discharge, as shown in the oscilloscope image that follows.

This waveform is somewhat over-damped, suggesting that a lower damping resistor would improve velocities by reducing the dreaded suck-back effect.

The oscilloscope image above indicates peak currents with capacitor charge of 160v and peak current of:

![]()

We don’t expect this SCR to survive much more than 1300 A in this application.

| < Previous | Page 34 of 37 | Next > |

©1998-2024 Barry Hansen